Industrial maintenance and maintenance planning with Jira, Confluence and catworkx Apps

The perfect balance between corrective and preventive maintenance is the supreme discipline of maintenance planning. If you perform too many preventive measures, you will carry out unnecessary repairs, spend your maintenance personnel unnecessarily and replace worn parts too early. If you perform too few preventive maintenance tasks, you run the risk of causing avoidable machine shutdowns that result in high downtime costs. The only way to get the right mix is to consistently collect, evaluate and synthesize data on your people, machines, shutdowns, downtime costs and spare parts.

Get started!Preventive vs. corrective maintenance

Corrective maintenance

Corrective maintenance means that maintenance activities are carried out when the function of the machine or plant is limited or prevented. This maintenance strategy is to be pursued if necessary redundancies exist or if downtimes do not cause significant costs.

Preventive maintenance

Preventive maintenance includes all activities that prevent machine downtime. These can be cleaning or maintenance tasks that are performed in a regular and planned manner. The planning of these tasks is calendar-based or condition-based. Production data such as the number of pieces or machine hours can also be included in the planning of preventive maintenance.

Ratio of immediate corrective maintenance

Immediate corrective maintenance is the type of maintenance that should be prevented as far as possible. Immediate corrective maintenance means that a machine or plant fails without warning. Depending on the criticality of that machine or equipment, significant damage can occur. The downtime costs of a machine depend on personnel costs, material costs and dependencies to other machines in the production line. Often these downtime costs are measured in minutes rather than days or hours and can be in the four-digit range. This is not only expensive, but also causes stress for your maintenance staff. Because they have to drop everything and take remedial action within the shortest possible time. Not only does this cause employee dissatisfaction, but it also increases the likelihood that repairs will not be carried out properly and that faults will therefore soon reoccur.

The health of a maintenance organization should therefore be measured, at least in part, by the ratio of immediate corrective maintenance to preventive or planned corrective actions. A rule of thumb should be that a ratio of 20/80 is not exceeded - Where here the number of incidents and not downtime or man-hours are used as the unit of measurement.

Mechanical Engineering

STAGIL Assets helps you to arrange and structure your machine tree in a meaningful way. All machines and assets are put into a hierarchy here. Different types of machines get their asset types with the fields that make sense for the respective machine. All data fields that are available as custom fields in Jira can be used for your machines and assets.

(Mobile) Dashboards and To-Do's

Each of your maintenance staff gets to-do's directly into their backlog. Maintenance planners can plan the daily schedule of your maintenance staff and prioritize tasks. In the end, all employees can view and work through their daily, weekly or monthly schedules directly on their mobile devices and book their working hours to the respective tasks.

Data analysis and conclusions

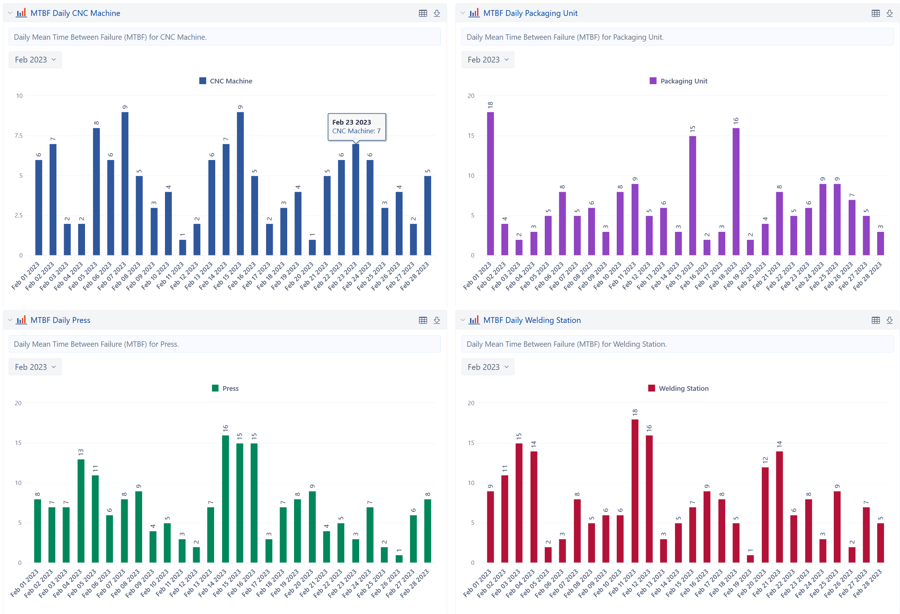

Maintenance KPIs are performance metrics that relate to the reliability of your machines as well as the performance of your maintenance team. These include a ratio of immediate corrective maintenance, MTBF, MOTBF, MTTR, MWT and many more. All performance metrics can be broken down into different departments, locations, teams, cost centres or other instances using Jira and STAGIL Assets. This allows you to identify and fix common sources of errors. Data analysis also helps you define and adjust optimal preventive maintenance cycles as needed.

Completion codes for root cause analysis

In order to track down the cause of recurring faults, it makes sense to introduce completion codes for maintenance. Examples are wear and tear, incorrect handling, insufficient preventive maintenance and many more. These can be evaluated and analyzed for different machines, locations, teams or other instances. In this way, future errors can often be avoided.

Checklists for inspections

catworkx Tables and Checklists allow you to generate checklists for inspections. This way you can record all important parameters for the inspection of a machine and derive the need for action for further maintenance measures. Depending on the values you enter in the checklist during an inspection, further preventive maintenance measures can be commissioned automatically. The scripts and automatisms required for this are provided by catworkx based on your requirements.

ERP and BDM connection for spare parts and machine capacities

In order to make even better decisions for maintenance, it can make sense to create a connection between ERP and BDM data. This way, stock levels and usage for spare parts as well as production data can be included in the analysis.

Related Solutions:

Asset Management

Time Tracking

CMDB

SLA and Queues

Incident Management

Mechanical Engineering

Apps and software for your maintenance system:

STAGIL Assets (Advanced links management & Data model)

Atlassian Jira

Jira Service Management

Our Services:

Consulting

We are happy to advise you in detail and personally regarding the Atlassian products and our services around Atlassian.

Configuration

Talk to our experienced consultants who analyze potential and agree with an optimization plan.

Support

No matter if you are new to the Atlassian Suite or just need a hand with a certain topic – we are glad to help.

Development

Do you need special functions that are not covered by any existing app? We develop your own apps individually adapted to your needs.

Hosting

We are helping you to reach the availability that you need by offering several different service level categories with up to 99.9% availability.

Trainings

Teams of up to 8 can schedule private sessions, either online, or we’ll come to your site and deliver Team (Onsite) classes.

Licenses

We offer attractive package benefits and advise on advantageous options for buying or extending Atlassian licenses.

Optimization

We stabilize your atlassian systems and make sure they always run perfectly!